With Canadian winter temperatures dropping far below freezing, it makes sense to be prepared well in advance of inclement weather, and it’s not too late to start. For some facilities, this means installing insulation to ensure process lines and control devices remain warm and ensuring measurement and control equipment is protected from the environment.

It’s not uncommon to see process lines insulated in Canadian facilities. Insulation serves various purposes. It may exist to provide personnel protection against hot process lines, or it may help to keep fluid warm and flowing. When insulation is used on steam or gas lines containing entrained liquids, or gas lines with potential for condensate formation, heat is retained for a longer distance, and for a longer period of time.

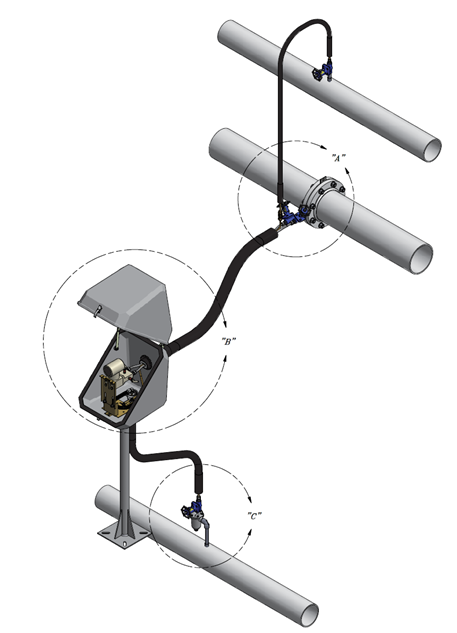

To help mitigate freezing of lines and damage to critical process monitoring and control equipment, Tundra provides O’Brien instrument enclosures and O’Brien tube bundle (which can be pre-insulated and/or heat traced).

Where is freezing a concern and what can you do? Here are a few examples:

- Steam travelling in lines for process or heating purposes will eventually condense, and steam condensate (water) is formed. At a point of measurement (E.G. differential pressure or pressure), a tap is placed on the line and tubing is often run to a measurement device. It is here that condensate can collect and can quickly freeze during cold winter months. This can impair critical measurement and facility safety, cause catastrophic line breaks, and can also damage monitoring instrumentation.

- To mitigate the potential for freeze-related issues, O’Brien enclosures can be installed around instrumentation to keep the sensing components warm while maintaining the proper fluid state within the line. O’Brien enclosures may have a transmitter mounted inside and rely on process heat combined with enclosure insulating properties to keep a transmitter warm, or the enclosure can be fitted with an internal regulated heater to maintain warmer temperatures.

- Pressure is also monitored on process gas lines, as well as other services like instrument air supply to valves. These lines may also contain liquids (or the potential for liquid formation), and again the potential for freezing exists. Heated O’Brien enclosures mitigate the potential for freezing at the point of measurement while protecting measurement equipment from the environment. Additionally, on devices with an LCD display (rated to -20 Deg. C), O’Brien enclosures with an integral window allow operations staff to visually confirm process conditions in lieu of a mechanical gauge.

- Level is monitored on a variety of vessels, and liquid contained within the line between vessel and transmitter may freeze. O’Brien enclosures help to maintain a liquid state at the measurement device.

O’Brien pre-insulated and heat traced tube bundle options will also help ensure facility up-time while reducing install time vs. conventional tubing and removable insulation blankets. Tubing is used to transport extractive analytical samples, to connect process lines to instrumentation for measurement and monitoring, and to transport steam from a boiler to a facility for process heating. O’Brien tube bundle is pre-insulated and available on spools of varying lengths for ease of installation. O’Brien tube bundle may be insulated for lines that are already warm, and may also incorporate additional steam trace tubing or electrical heat tracing to provide additional heat.

If you’re looking to winterize a facility, Tundra can help. Learn more about O’Brien products here:

Enclosures: https://tundrasolutions.ca/ac-category/instrument-enclosures/

Tube bundle: https://tundrasolutions.ca/ac-category/tube-bundle/

Get Email Updates

Stay connected and sign up to our email list to be the first to hear about the latest news, events, training, and special offers.